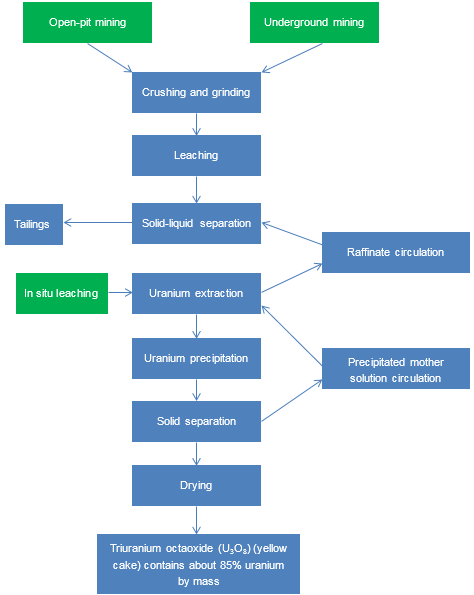

There are three kinds of ways to explore the main uranium ore: In-situ leach mining, open-pit mining and underground mining. There is about 48% of natural uranium produced by virtue of in-situ leach mining in the world, 46% from the conventional mining method (open-pit mining and underground mining), and 6% extracted as other minerals and by-products.

Uranium Mining Production Process

In-Situ Leach Mining

In-situ leach uranium mining is a process in which the leaching solution is injected into the permeable ore-bearing aquifer by means of the liquid injection borehole, so that the leaching solution is in contact with uranium in the penetration process for dissolution reaction, so as to generate the uranium solution; and the solution is extracted to the earth surface by virtue of the extraction hole, and then delivered to the workshop for processing, so as to obtain the uranium product.

? It is applicable to uranium mineral mining in water-bearing and permeable sandstones.

? The cutoff grade of delineated uranium ore is 0.001%.

? According to different leaching mechanisms, there is acid process mining and alkaline process mining.

Application Conditions of Mining:

? The ore-bearing lithology shall be permeable sandstone and glutenite. The ore body is hosted in the ore-bearing aquifer below the groundwater. Abundance and permeability are decisive factors whether in situ leaching is feasible.

? With gentle orebody occurrence (the dip angle is generally less than 10 degrees), the top and bottom boards shall be well-sealed impervious beds.

? The uranium amount per square meter of the ore deposit shall be above the lowest economic indicator. The acid process leaching shall not be applied when the content of carbonate in the ore-bearing aquifer is more than 2%. Quartzose arkose or quartzy sandstone shall be optimally served as the surrounding rock.

? Based on the current uranium price, the maximum buried depth of the exploited ore body shall be no more than 400-600m.

Leaching Mechanism

Acid process

The sulfuric acid is mainly served as the leaching agent. Uranium in the ore is changed from the precipitation state to the dissolved state to generate the uranium sulfate solution when the pH value of the leaching solution is reduced to be 2. More than 2% of carbonate in the ore-bearing aquifer is not applicable.

Alkaline process

Ammonium bicarbonate is mainly used as the leaching agent. The hexavalent uranium in the ore is complexed with carbonate (CO32-) in the carbonate to generate the uranyl carbonate solution when the pH value of the leaching solution is risen to 9 or higher. The content of liquid uranium is low, and the ammonium salt also results in groundwater pollution.

CO2 + O2

The principle refers to that ores are oxidized by O2, and HCO3- ions and uranium in the deposit are reacted to dissolve uranium in the solution when CO2 is added into the groundwater. It also belongs to alkaline leaching classification.

Bacterial leaching

Thiobacillus ferrooxidan is mainly selected to exert indirect catalysis in the leached uranium process, which can promote oxidation of pyrite and ferrous sulfate and generation of hexavalent uranium. Acid consumption can be reduced. It needs to be used in cooperation with the acid process, which is not an independent leaching method.

Main advantages of in situ leaching are as follows:

? The mining method is safe and simple, and the process flow is short. Minerals handling and crushing are not needed in the mining stage and ore grinding and solid-liquid separation are not needed in the hydrometallurgy stage. This shortens mining and metallurgy processes and lowers direct production cost.

? There is short mine construction period, little construction investment, low labor intensity, high degree of automation, and low depreciation of fixed assets.

? The environmental pollution is low. Firstly, pumping and injecting are essentially balanced, the in situ leaching solution is recycled in the closed pipe, and the discharge amount of wastewater is significantly reduced; secondly, the radioactive dust pollution is thoroughly improved; thirdly, the pollution of tailings and exhaust gas is minimized.

Open-pit mining is a process in which the covering is removed from the ore body, and then the uranium mineral is mined from the stope of the open earth surface. It is mainly applicable to uranium deposit mining buried shallowly of the main ore body.

Main advantages include:

? Short infrastructure period. 2-4 years/large;6-8 months/small.

? Large mining space and high labor production ratio. 2-10 times higher than underground mining.

? Small ore losses and dilution ratio. Loss ratio: 3%-5%; dilution ratio: 5%-8%.

? Low mining cost, good labor conditions and safe production.

Main disadvantages:

? Mining is greatly affected by climate.

? The infrastructure equipment investment is high.

? The mine covers a huge area, resulting in great damage on the surface environment.

Underground mining is a process mining ores from ore blocks of the subterranean deposit by virtue of tunnel extracting engineering, which is realized by deposit extracting, accurate ore block mining, cutting and recovery. It is mainly applicable to uranium deposit which is buried deeply and does not allow open-pit exploitation. On the basis of the ground pressure handling method, it is divided into open stope method, cut-and-filling stoping method and caving mining method.